| [ site map

]

MODULAR ROBOT INTRODUCTION

|

MODULAR ROBOTICS & ROBOT LOCOMOTIONAn automated manufacturing system usually consists of a collection of material processing and handling devices such as CNC machines, robots, part feeders, conveyors, and sensors. These devices are traditionally designed and commissioned with the intent that they will be operated with few significant changes so long as the specific product is being manufactured. Certain flexibility has been given to those devices through programmable controllers. However, it is time-consuming and not cost effective to reconfigure them for other products. In the rapid-changing and highly competitive global economy environment, such drawbacks reduce the attractiveness of automation systems for manufactures that are involved in high-mix, low-volume production. For manufacturers adopting the fixed automation systems, not being able to respond quickly to market changes will place them at a disadvantage. The Nanyang Technological University and Gintic Institute of Manufacturing Technology thus initiate a project aiming at improving agility and flexibility in automated manufacturing systems. Instead of focusing on the outcome from a manufacturing system, the

project here looks into changing the architecture of the manufacturing

tools so that they can be rapidly configured and deployed based on the

functional needs. The key to the concept of rapid reconfiguration and

deployment lies in the "plug-and-play" component-based technology. In this

project we aim to develop a rapidly reconfigurable robotic workcell. As

the robots are complex elements in a manufacturing cell, kinematics,

control and coordination of robotic systems are sophisticate compared to

other elements/equipment in a cell. A reconfigurable robotic workcell can

fairly set the benchmark on the future trend of reconfigurable

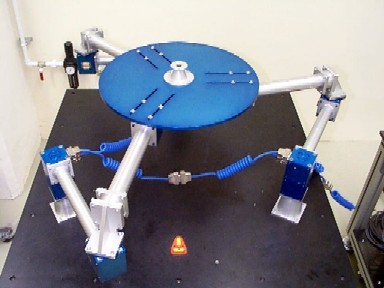

manufacturing systems. In the proposed system (Figure 1), workcells are

made of standard interchangeable modular components, such as actuators,

rigid links, end-of-arm tooling, fixtures, and sensors. These components

can be rapidly assembled and configured to form robots with various

structures and degrees of freedom (DOF). The robots, together with other

peripheral devices, will form a complete robotic workcell to execute a

specific manufacturing task or process. The corresponding

intelligent control and simulation software components are then

reconfigured according to the change of the workcell configuration. The

maintenance and upgrade of the system are simplified by replacing the

malfunctioned or outdated components. Converting a manufacturing line from

one product to another can be very fast in order to keep up with the

rapidly changing marketplace.

OBJECTIVES The objective of this research project is to develop a set of software and hardware tools for reconfigurable manufacturing automation based on Component Technology to enhance the competitiveness of Singapore’s industry. The realization of the reconfigurable automation is through the construction of a reconfigurable robotic workcell. The following five major aspects are covered in the development of a reconfigurable robotic workcell prototype, namely: 1) Robot/workcell

hardware component design

To cope with rapid change of task requirements in the production line while maintaining inter-operability of components, using mixed-module design is necessary. Robots with serial, parallel, or hybrid geometries can be constructed for tasks requiring different accuracy, stiffness, and dexterity, etc. Key components, such as actuators and grippers/fixtures, can be interchangeable among different robots and devices. In principle, all of the robots and motion stages in the workcell are constructed using standard fixed-dimension modules and easy-to-fabricate variable-dimension modules. The fixed-dimension modules include active and passive joint modules and gripper modules that can produce rigid motions. The variable-dimension modules consist of rigid links, connectors, and platforms that can be designed and fabricated in a very short time. Through the use of mixed types of modules, task-optimized workcell configuration design and rapid deployment can be achieved at the same time. A.1 Fixed-dimension modules

Pivot Module, Revolute

Module & Spherical Module Pivot Module, Revolute

Module & Spherical ModuleB. Reconfigurable & “Plug-and-play” Robot Modelings For a robot system built from modular components without fixed DOFs and geometry, the derivation of the kinematic and dynamic models becomes difficult, as there are almost endless robot configurations to be considered. Conventional robot controllers require the kinematic models of the robot to be manually derived and hand-coded into the system. In principle, this is not suitable for reconfigurable robot systems. A new framework is proposed to automate the robot model generation process. This framework consists of a component database, a representation of modular robot assembly, and geometry-independent modeling techniques. The database stores the static CAD data of the components. A kinematic graph representation of the assembly configuration of a modular robot, termed an Assembly Incidence Matrix, keeps track of the dynamic robot configuration data. Geometric modeling techniques based on the Product-Of-Exponentials formula (POE), the modern approach for rigid body screw motion, utilizes both static and dynamic data to generate the required models. When the robot is reconfigured, the corresponding kinematic and dynamic robot models are reconfigured accordingly and are ready for control and simulation. This approach can be applied to all serial-typed robot configurations and a class of parallel-typed robot configurations. Unlike conventional robots using Denavit-Hartenburg (D-H) parameters for kinematics models, the kinematics of modular reconfigurable robots is formulated based on the Local Product-of-Exponentials presentation. The POE modeling method can uniformly describe the robot joint axes using generic line coordinates regardless of the type of the joints. Also due to the fact that POE is a complete description of the rigid body motion, not a minimal representation like the D-H parameters, the formulated robot kinematics has robust performance on the singularity problems arisen in kinematic calibration and numerical inverse kinematics. In this research, we have developed the following robot models using POE approach. C. Robot Configuration Optimization Because of the modular design, the reconfigurable workcell system can achieve optimal design at the component level but may not obtain optimal performance at the system level. Task-driven robot configuration optimization becomes necessary to establish sub-optimal performance for the overall robotic workcell. Typically, the problem of robot configuration optimization can be stated as "finding an assembly of robot modules that can achieve a certain task requirement based on an inventory of modules." The assembly of a reconfigurable robot can be treated as a compound entity with finite number of constituents. Finding the most suitable task-oriented robot configuration then becomes a discrete design optimization problem. A task performance related objective function is formulated. Discrete optimization techniques, such as Genetic Algorithms (GA), the simulated annealing method (SA), and other artificial intelligence techniques are employed to find solutions. However, due to the complexity of the problem involved, the computation effort required for GA and SA is tremendous. To alleviate the computation problem, we are using the "software agent" concept to determine the optimal configuration. Our proposed master-slave agent architecture for solving the problem of robot configuration optimization is shown here. In this architecture, the slave agents, also the mobile agents representing arbitrary robot configurations will be dispatched to a cluster of networked computers. Kinematic agents, which are resided on the networked computers, evaluate the performance of and improve a dispatched robot configuration individually. The master agent controls the dispatch of a pool of slave agents, provides two-way communication among the kinematic agents, and determines the task-optimal configuration based on the messages sent back by the kinematic agents. Because the computation of optimal robot configurations is executed in a distributed and asynchronous manner, the proposed agent architecture can be scaled up to determine the optimal configurations of multiple robots under different task requirements simultaneously, and thus, achieves concurrent design of multiple robots with multiple-objectives. Note that the proposed approach is a generic implementation. The criteria used in selecting the optimal configuration depend largely on the task requirements and the performance of the robots. We have proposed a Minimized DOF philosophy to minimize the total number of actuator modules employed in a serial-typed modular robot for a given task. With less number of modules, the robot can carry more payloads instead of the distal modules. Furthermore, the robot can be operated at higher speed with better dynamic response. D. Control and Communication The control of a reconfigurable workcell and its devices requires: 1) the capability to cope with reconfiguration of devices, and 2) task coordination among devices. Therefore, two levels of control are used in the workcell: supervisory control of the workcell activities and real-time control of individual workcell devices. The workcell supervisor performs supervisory control of the devices and coordinates the workcell activities by collecting reports from the device controller regarding the status of the workcell, and then, based on these reports, dispatching device task instructions to the device controllers. The device controllers control the individual devices. Each device controller is equipped with its own real-time control system to ensure that the assigned tasks are completed properly. The control and communication architecture of the workcell is illustrated below. E. Simulation Software for Robot/Workcell To visualize and simulate the performance of an assembled robot, such as reachability and workspace, a robot simulation software application is necessary. The Simulation Environment for MOdular Robot Systems (a.k.a. SEMORS) is a Windows NT based object-oriented software application developed for this project. Based on the proposed Local POE models and AIM data structures, SEMORS can offer uniform model construction effort (kinematics, dynamics and calibration) across computer simulation and real-time control of arbitrary robot configurations. SEMORS is intended to be a uniform interface for all modular robots and is portable to modular robot systems from different vendors. It will be used both for simulation and for on-line execution of a task, regardless of whether the robot is executing (or is simulated to be executing) the task as a stand-alone application, or as part of a workcell process. Thus, it allows the user to quickly integrate the hardware components into modular robots, and to manage their operations in the reconfigurable workcell. Key features of SEMORS include: DEMO WORKCELLS To illustrate the effectiveness of the completed reconfigurable automation tools, both hardware and software, we have physically implemented several prototypes of the reconfigurable robotic workcells in various geometric configurations for different task requirements. Light-machining workcell (multiple robots)Copyright © 2002 Modular robotic & Robot locomotion Group, School of MPE, NTU |