Petri net to PLC converting:

IO mapping and Validation

2021, Hugo Barroso & José Gaspar

Introduction

Designing Petri nets (PN)

with input/output (I/O) is a way of designing programs for PLCs. A PN with I/O

interacts with a system or, in other words, supervises a system. A PN typically

has inputs at the transitions and outputs at the places. See in figure1 the

arrows "PN actuation" meaning the outputs required to drive the

system and see "PN inputs" meaning the signals observed in the system

and used to drive the Petri net.

Figure1: Petri net supervising the system "HW to be

controlled".

This page provides a

software package that converts a PN with I/O to PLC-code, completed with

verification / validation features. Verification and validation are based on

reachability analysis and allow the assessment of error-free PN to PLC-code

conversion.

One challenge of doing

validation by reachability analysis is the so-called state space explosion. We

consider (accept) only bounded PNs based on the construction and analysis of

the coverability tree.

Concepts

The Petri net is

represented by its incidence matrix, D, and has inputs / outputs associated to

transitions and places, respectively. The matrix D has size n lines by m

columns, where n denotes the number of places and m denotes the number of transitions.

Matrix D=D+-D-. In code, the D+ and D-

matrices are usually denoted as Pre= D- and Pos= D+. The

initial marking is denoted as mu0.

Verification and validation

allow comparing the behavior of a PN with the discrete event system running on

a PLC, from a black box perspective: one generates PLC inputs and should obtain

PLC outputs as designed by the PN complemented with I/O.

The black box test involves

showing the PLC reaches all reachable states, by providing the right input

events at the right times. These events are automatically generated based on

the coverability tree of the PN.

Validation of the PLC

program means testing desired behaviors. These behaviors can be represented

also as PNs and therefore explored in conjunction with the PN implemented in

the PLC. Usually one creates a storyboard (a PN with I/O) which is combined

with the PN implemented in the PLC, and a complete system reachable set can

then be generated for a black box test.

Package Download and

First Test

[Instructions

for Windows]

Install

an SVN client, e.g. the freeware TortoiseSVN ** including its command line

tools **.

A reboot

may be required after installing TortoiseSVN.

In

Matlab run the following lines:

% go to a folder where you can receive files retrieved by SVN

% the next line is long (ends at /sww)

!svn co --username pn2plc

--password coverability

svn://svn.isr.tecnico.ulisboa.pt/dccal/msc/plc_verif/sww

cd sww

addpathx('.')

cd test

cd exp1_PN_sim

tst

Tests Contained in the

Repository

The design of the PNs with

IO, the starting point of our conversion and validation toolchain, is based on

the IOPT tools:

http://gres.uninova.pt/IOPT-Tools

Our PLC code production

toolchain is applied on the PNs with IO, therefore allowing to verify whether

the PNs are correctly translated to PLC ST programs.

The

repository contains three experiments in three separate folders:

exp1_PN_sim

exp2_IOPT_to_ST

exp3_PLC_Unity_tst

The first experiment,

in folder exp1_PN_sim, loads a PN with IO (a .pnml file), finds the

reachable set of the PN, and generates events to reach all possible states.

Figure 2 shows the results.

Figure 2: Test of a PN with IO. Top plot shows an automatically generated sequence that drives the PN through all the reachable states. The other two plots show the state of the PN and the generated outputs.

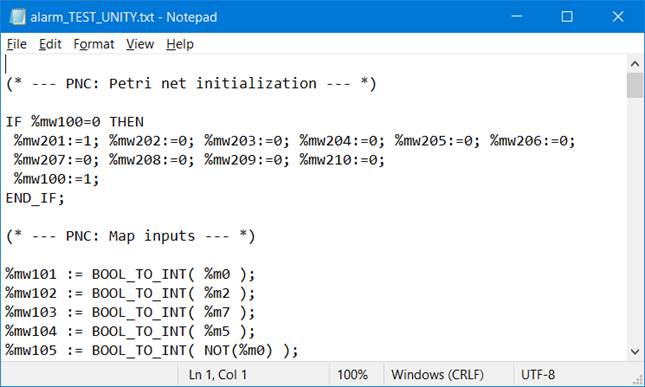

The second experiment,

in folder exp2_IOPT_to_ST, tests the conversion from PN to PLC-code

(Structured Text). Figure 2 shows a sample of lines of code generated. See the

full code in the folder, file "alarm_TEST_UNITY.txt".

Figure 3: Sample lines of the PLC-code generated from a PN.

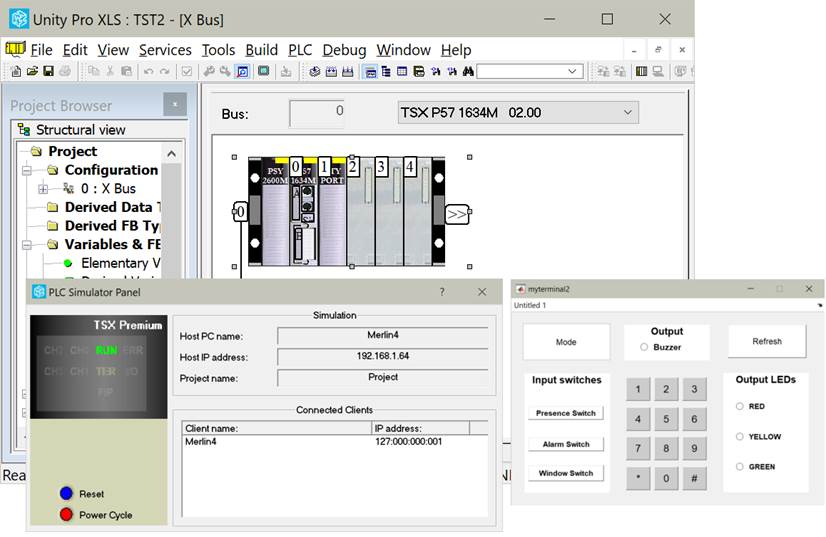

The third experiment,

in folder exp3_PLC_Unity_tst, involves the PLC development environment,

Unity Pro (v13), which is contacted by a client running in Matlab (see Figure

4).

|

(a) Setup with one input and one output modules

(b) Setup based on a single input and output module |

(c)

Simulated-hardware setup. The input and output are mapped on the PLC memory. |

Figure 4: Schneider's PLC development

environment, Unity Pro, interacting with a client running in Matlab.

Maintenance &

Acknowledgement

This software is distributed

in the hope that it will be useful, but without any warranty; without even the

implied warranty of merchantability or fitness for a particular purpose.

In case you find this

software useful and do any publication in the sequel please cite the paper:

"Validation of

Discrete Event Processes implemented on PLCs based on Petri Nets", Hugo

Conde Barroso and José Gaspar, IEEE International Conference on Autonomous

Robot Systems and Competitions (ICARSC) 2021.

Contact

|

Prof. José Gaspar Instituto de Sistemas e Robótica, Instituto Superior Técnico, Torre Norte Av. Rovisco Pais, 1 1049-001 |

Office: Torre Norte do IST, 7.19 |