Schneider Premium PLC Hardware Interfaces

& Signals Monitoring

October 2015, José Gaspar

Introduction

Schneider Premium P57 PLCs

can be equipped with various types of input and output modules. In the Industrial

Automation course the PLCs, P57 1634/2634, are equipped in two main

configurations:

(i) two separate discrete input and output modules,

namely the DEY16D2 and the DSY16T2, or

(ii) a single discrete input and output module, namely the DMY28FK.

The requirement to have

laboratories equipped for serving multiple shifts of classes is better served

if each group of students can plug / unplug their specific hardware terminal.

Figure1 shows terminal hardware used in the laboratories of the Industrial

Automation course. Separate wiring to each of the inputs and outputs make the

changes of hardware terminals slow processes and likely sources of wrong

connections.

Figure1: Input and output based in single conductor wires. This solution

is still based in the use of screw terminals, which accounts for time consuming

and error prone plugging of terminal hardware.

The problem hardware

terminal changes is almost none for the DMY28FK, as it has I/O accessible by

flat cables (2x 20pin IDC), which can be easily plugged / unplugged at the

beginning / end of the classes. It is however an issue for the DEY16D2 and the

DSY16T2 as they have a screw terminal for each of the 16 input/output bits. The

modules DEY16D2 and DSY16T2 allow using terminal blocks, but that solution does

not allow fast interchange of terminal hardware with the module DMY28FK.

In this page is presented a

printed circuits solution to allow easy sharing (interchange) of terminal

hardware between the module DMY28FK and the modules DEY16D2 and DSY16T2. Printed

circuits are used to connect the IDC flat cables to individual wires by

soldering. Complementarily, inexpensive terminal strips can be used to connect

/ disconnect the individual wires to the terminal hardware.

Given the flat cables

interface, it is also shown (later in this page) an application where an

Arduino is used to monitor the input and output signals of a PLC.

Flat cables interface

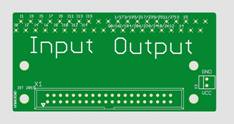

Due to the personal

computer (desktops) market, 40wire flat cables are still nowadays inexpensive,

and very common to find and buy. 40wire flat cables were therefore chosen as

the interface on the side of the terminal hardware. Module DMY28FK offers 2x

20wire flat cable interfaces. Buying four 20wire female IDC plugs for each

40wire flat cable allows building two cables, each one allowing to connect one PLC to one terminal. See in figure2 (top row)

the connection between the DMY28FK and the hardware terminal. The PCB in the

hardware terminal side has a 40wire IDC-female to receive the 40wire IDC-male

of the cable.

Figure2: Input and output based in flat cables. Top row shows the flat

cable connection between the DMY28FK and the terminal hardware. One PCB is used

to convert the flat cable into individual wires. Bottom row shows the flat

cable interface between the modules DEY16D2 and DSY16T2, and the terminal

hardware. In this case are used 3 PCBs, two to connect with the PLC modules and

the other one as before on the terminal side.

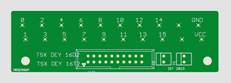

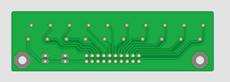

As referred, modules

DEY16D2 and DSY16T2 have screw terminals. Two PCBs have been developed to

convert screw terminals into 20wire IDC cables, which allow then the

inter-change of hardware terminal with the DMY28FK. See figure2, bottom row,

pictures of the final assembly of terminal hardware with the PLC.

Figure3 shows the manufactured

PCBs boards, adapting the inputs/outputs of the modules DEY16D2 and DSY16T2 to

the terminal hardware. Note that in the case of using module DMY28FK, the two

20wire IDC PCBs are not necessary, as the module interfaces are already in the

form of 20wire IDC.

Figure3: PCBs for connecting individual wires to flat cables. Top row

PCBs allow using modules DEY16D2 and DSY16T2 with 20wire flat cables, similar

to the DMY28FK. Bottom row shows a 40wire interface to use on the terminal

side. Common 40wire flat cables link 40pin IDC to 2x 20pin IDC (the cables are

split in half at their middle length).

Cost

The cost of the PCBs, plugs,

components and cables, necessary to equip ten workbenches (PLCs), was in the

order of 300euro. IDC20 plugs, male and female, were found to be more expensive

than the IDC40 plugs - that was one of the reasons for selecting IDC40 on the

side of the terminal hardware.

Note that now the cost for

preparing more hardware terminals is reduced to just the IDC40 PCB. This low

cost is helpful as it allows having multiple shifts around the same PLCs, since

plugging / unplugging terminal hardware is fast and connections-error-free, as

required to be done at every begin / end of a class.

PLC Signals Monitor

The flat cables interface allows

inserting, and taking away, devices in between the PLC modules and the terminal

hardware in a fast and connection-wise error-free manner. A device frequently

necessary to insert in the circuit is the signals generator and monitor.

Generating and monitoring the signals between the terminal hardware and the PLC

is of particular importance for systematic testing and debugging of

applications.

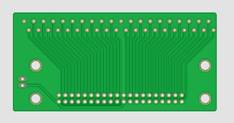

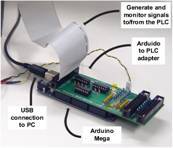

Figure4 shows a PLC signals

monitor built with IDC40 interfaces to be inserted between the terminal

hardware and the PLC. The monitor is based in an Arduino Mega and some hardware

converting 5VDC to/from 24VDC. The monitor records all signal changes found in

the digital signals generated by the PLC and by the terminal hardware. The

monitor is also able to generate signals and in that way simulate signals that

make the PLC program work in a specific sequence and therefore help debugging

the application.

Figure4: PLC input and output monitor and signals generator. PCB with

the IDC interfaces (left). Generator mode requires a single flat cable

(middle). Pass-through mode, the monitor records signals generated by the PLC

and the terminal hardware.

Downloads

** Not yet

available **. Under

study the way to make publicly available the hardware here described.

Maintenance

The hardware described in

this page was created mainly for the purpose of helping classes. There is no

continuous maintenance other than the requirements associated to the classes.

The information and files

in this page are distributed in the hope that they will be useful, but without

any warranty; without even the implied warranty of merchantability or fitness

for a particular purpose.

Acknowledgments

Thanks to Henrique Gonçalves, Manuel Ribeiro and

Ricardo Nunes for helping with the design and the

implementation.

Hardware was mostly

financed by the Systems, Control and Decision scientific area of the EEC Department.

In case you find this

material useful and do any publication in the sequel please refer to the course

Industrial

Automation at Técnico,

Contact

|

Prof. José Gaspar Instituto de Sistemas e Robótica, Instituto Superior Técnico, Torre Norte Av. Rovisco Pais, 1 1049-001 |

Office: Torre

Norte do IST, 7.19 |