Industrial Automation Course at ULisboa

Use Ethernet to Log PLC Strings

2023

José Gaspar

Introduction

This webpage has the purpose of

providing one coding example where one PLC creates text messages which can be

logged by a remote PC. The logging is realized with a Matlab function, running

in the PC, that uses the ethernet connection to poll the memory of the PLC. The

connection protocol is Modbus.

Log

PLC Strings Generated by the PLC Simulator

Download

the Unity Pro project stored in the zip file

and unzip

it. After downloading and unzipping the project, compile and transfer the

project to a simulated PLC (part of Unity Pro). Then launch the Matlab function

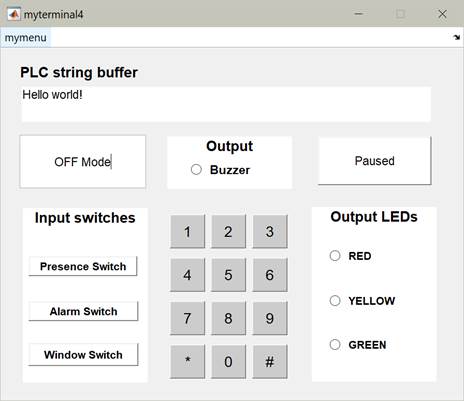

myterminal5, see Figure 1(a).

Running myterminal5 allows showing a string created by the PLC. Unity

Pro allows the PLC to generate other strings. In Matlab:

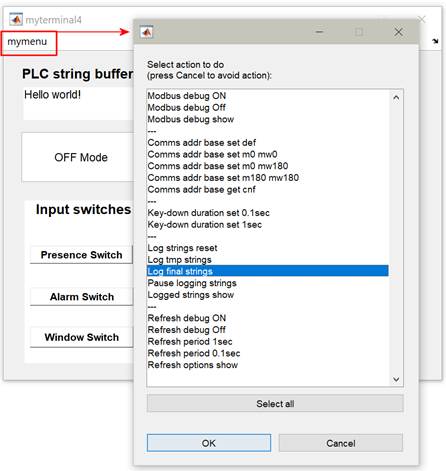

myterminal5 > mymenu > Log final strings

allows

collecting (logging) a sequence of strings. Explanation: Matlab / myterminal5

are constantly polling the PLC memory and save any novel strings appearing in

the PLC memory.

|

(a) Virtual terminal that

communicates with the PLC. Keys are available provided keyboard columns are

energized. The PLC string buffer, a null terminated string starting at

%MW190, is displayed when the terminal is "Running". |

(b)

Options for communication, simulation times, strings logging and terminal

refresh. The commands "show" report mostly on the Matlab command

line. Command "Logged strings show" reports in a new window. |

|

Fig.1:

Virtual terminal running in Matlab connects to the PLC simulator using Modbus

(a). The virtual terminal allows logging strings after activation of option

"Log final strings" (b). Logged strings display is available by

clicking "Logged strings show". |

|

Log

PLC Strings generated by the real PLC

To avoid IP address

conflicts among many groups running the same code, the project (zip file

provided above) does not have the IP address configured. Therefore,

using the real PLC involves

configuring its IP address. Detailed

instructions to configure the IP address of the PLC:

http://www.isr.tecnico.ulisboa.pt/~jag/course_utils/plc_ip/p57_set_ip.htm

Having followed the instructions of the webpage

indicated in the previous paragraph to set the IP address, one would already

have the Matlab interface configured to connect to the PLC, using ethernet.

However, if one restarts Matlab, the connection information is lost, and

therefore one needs to inform Matlab, once more, about the IP address:

myterminal5

> mymenu > PLC IP change by hand.

Details

of Mixing Hardware IO with Virtual IO

Simulated

(virtual) IO allows developing and testing the PLC programs without the real

PLCs. The Matlab interface shown in Figure 1, effectively writes and reads

binary memories (and words) of the PLC. The list of binary and word memories used

in the PLC is easily shown in Matlab with:

myterminal5 > mymenu > Comms show addr and ip

The mixture

of hardware and virtual IO is based on two structured text sections, to be run

as the first and last sections of the Unity Pro (PLC) project. The first

section, mix_IO_ini sets each

input to true in case a binary memory indicates that. The last section, mix_IO_end reports to memories the current state of the

real outputs and resets the real inputs to the original values before the

overwriting guided by binary memories.

Explanation: The simulated

IO uses memories %M0 till %M19 (type EBOOL) where Matlab reads PLC information

(as PLC generated outputs) and writes simulated inputs. In addition, memory

words %MW180 till %MW199 (type INT) are used for communicating words and text

(strings). The referred PLC program sections, mix_IO_ini and mix_IO_end, (provided in the zip linked in the top of this webpage) implement simultaneously

real and simulated IO, by adding in the beginning of the scan cycle code as

%m20:= %i0.2.0; %i0.2.0:= write_input_ebool( %i0.2.0 OR %m0

);

and at the end of the

scan cycle code as

%m10 := %q0.4.0; %i0.2.0:= write_input_ebool( %m20 );

This code is adapted and

repeated for 8 inputs and 8 outputs.

Maintenance

The

software offered on this webpage was created for the purpose of being used in

classes. There is no continuous maintenance other than the requirements

associated to the classes.

This

program is distributed in the hope that it will be useful, but without any warranty; without even the implied warranty of

merchantability or fitness for a particular purpose.

Acknowledgment

In

case you find this software useful and do any publication in the sequel please

refer to the course Industrial

Automation at Instituto Superior Técnico, Universidade

de Lisboa, Portugal.

Contact

|

Prof. José Gaspar Instituto de Sistemas e Robótica, Instituto Superior Técnico, Torre Norte Av. Rovisco Pais, 1 1049-001 |

Office: Torre Norte do IST, 7.19 |